At Risoul we have more than 60 product specialists ready to help you.

We want to get to know your project. Leave your contact information and a member of our technical support team will contact you.

We want to get to know your project. Leave your contact information and a member of our technical support team will contact you.

We are a proud Hardy distributor, a brand recognized internationally for high quality products and solutions. We have over 22 sales locations in Mexico and a main office in Monterrey, Nuevo Leon

Hardy’s weight modules for AB controllers can be used in a white range of applications including batching/blending, filling/dispensing, check weighing, level by weight, force measurement, rate monitoring and more. These modules accurately transfer the exact weight directly to the controller. The modules use Add-On-Profiles for ease of integration.

Hardy weight processors are used as front ends to control systems or standalone for all types of general weighing applications. Operating blind or with a display, they reliably measure, condition and communicate weight without any need to control. Applications include inventory measurement, level measurement, batching/blending, filling/dispensing/dosing, and check weighing.

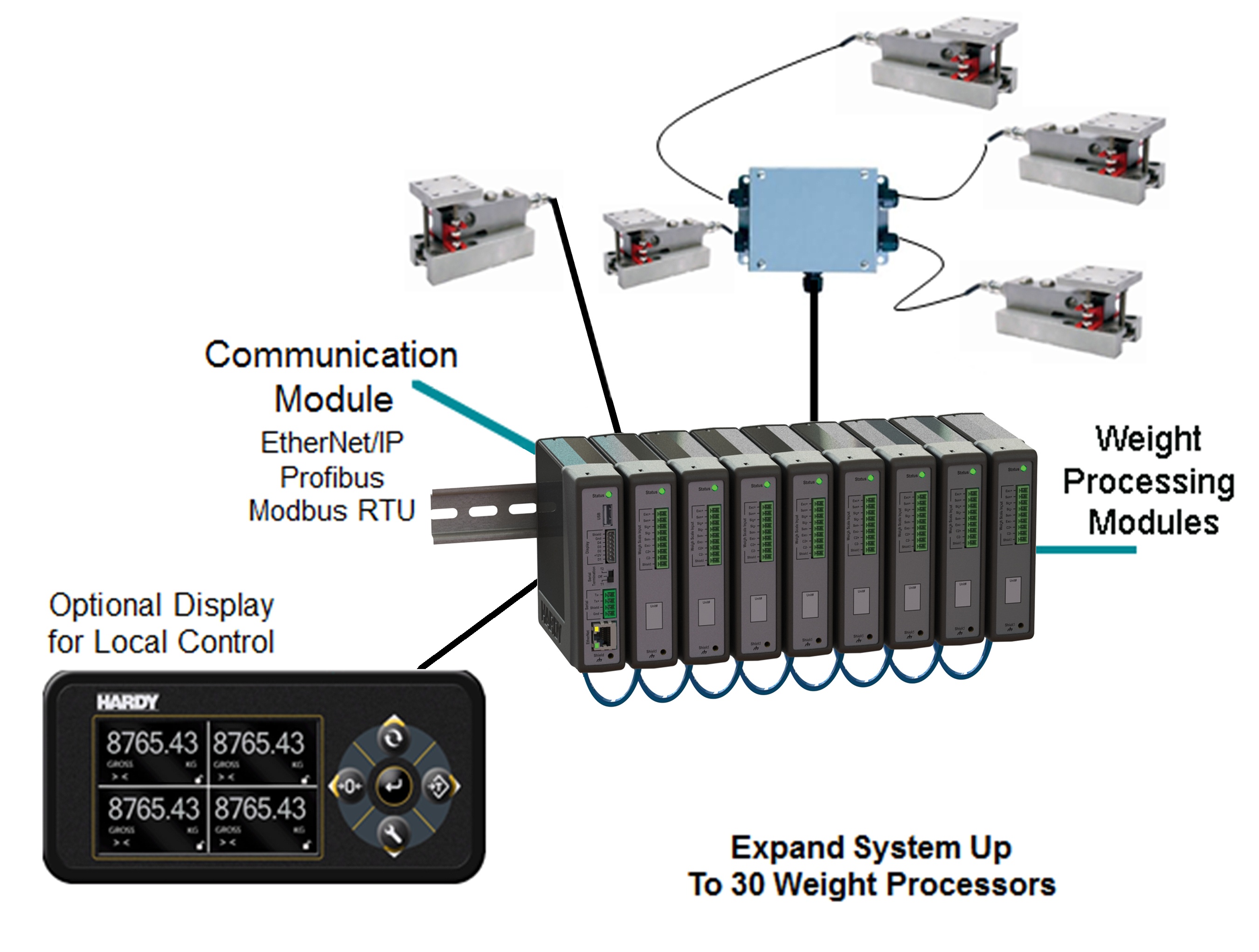

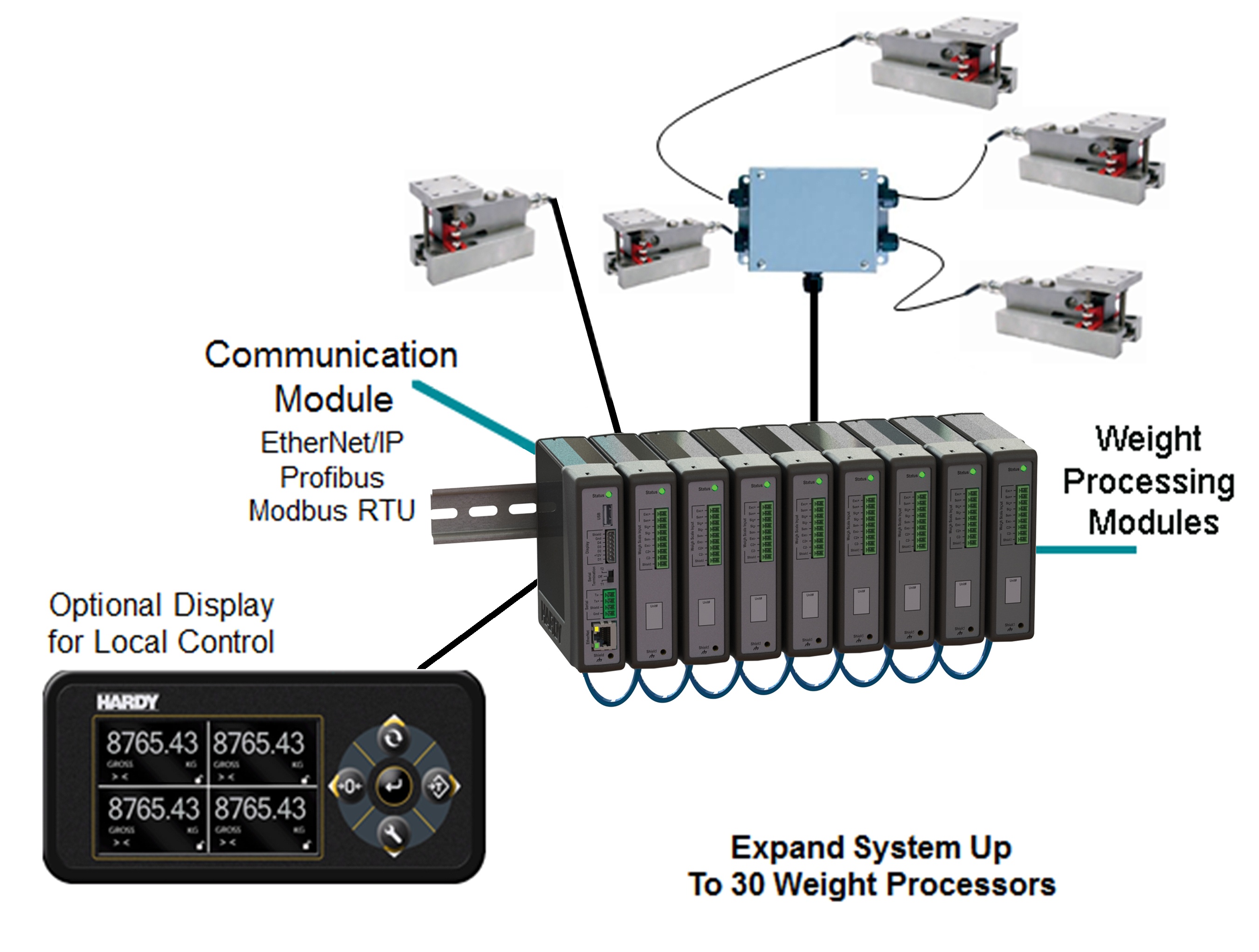

The Hardy 6600 series is a modular system of weight processors that deliver up to 28 channels of fast, stable, high-resolution weight readings. Each channel processes signals from up to four connected load cells then outputs the entire system’s weight data over Ethernet TCP/IP, Modbus RTU, Modbus TCP and either EtherNet/IP or Profibus-DP, depending on the Hardy Gateway Module.

Hardy compression load sensors include C2® electronic calibration data that reduces the plant's risk of accidents or contamination from using traditional test weights.

The Hardy ADVANTAGE® Lite Series of load point assemblies provides superior performance when compared to common load cells, as well as exceptional value, in meeting your weighing needs. Each pre-assembled load point consists of rugged stainless steel mounting hardware and a C2® Calibration compatible stainless steel, mV/V and mV/V/ohm matched and sealed load sensor. Each load sensor comes with 20 feet of 6-conductor cable and a color-coded wiring label to aid in installation. The sensors have an IP rating of IP67 and NTEP Class III certification.

he Hardy HI 6010 Summing box is a critical component in a weighing system that enables use of Hardy’s core technologies - C2® and INTEGRATED TECHNICIAN® (IT). A summing card with IT allows a weighing instrument operator to switch to the summing card’s internal test circuit and diagnose the entire weighing system from the front panel of the instrument or a remote location over the Internet.

Individual load cells can be isolated from each other for weight and voltage readings, allowing a technician or operator to quickly and safely troubleshoot weighing system faults and anomalies.

Hardy's INTEGRATED TECHNICIAN (IT) core feature helps you troubleshoot your weighing system and diagnose problems from the front of the instrument or via the PLC. Individual load cells can be isolated from each other for weight and voltage readings, allowing a technician or operator to quickly and safely troubleshoot weighing system faults and anomalies

Hardy's WAVERSAVER core technology eliminates the effects that surrounding vibration has on the scale weight signal, providing only true data for fast, accurate weight reading.

Access your instrument from any web browser. Use the incorporated web server to configure parameters from any Ethernet connection. This web server also provides remote access to control instrument and information parameters, further optimizing the production efficiency through real-time data exchange.

Hardy’s weight modules for AB controllers can be used in a white range of applications including batching/blending, filling/dispensing, check weighing, level by weight, force measurement, rate monitoring and more. These modules accurately transfer the exact weight directly to the controller. The modules use Add-On-Profiles for ease of integration.

Hardy weight processors are used as front ends to control systems or standalone for all types of general weighing applications. Operating blind or with a display, they reliably measure, condition and communicate weight without any need to control. Applications include inventory measurement, level measurement, batching/blending, filling/dispensing/dosing, and check weighing.

The Hardy 6600 series is a modular system of weight processors that deliver up to 28 channels of fast, stable, high-resolution weight readings. Each channel processes signals from up to four connected load cells then outputs the entire system’s weight data over Ethernet TCP/IP, Modbus RTU, Modbus TCP and either EtherNet/IP or Profibus-DP, depending on the Hardy Gateway Module.

Hardy compression load sensors include C2® electronic calibration data that reduces the plant's risk of accidents or contamination from using traditional test weights.

The Hardy ADVANTAGE® Lite Series of load point assemblies provides superior performance when compared to common load cells, as well as exceptional value, in meeting your weighing needs. Each pre-assembled load point consists of rugged stainless steel mounting hardware and a C2® Calibration compatible stainless steel, mV/V and mV/V/ohm matched and sealed load sensor. Each load sensor comes with 20 feet of 6-conductor cable and a color-coded wiring label to aid in installation. The sensors have an IP rating of IP67 and NTEP Class III certification.

he Hardy HI 6010 Summing box is a critical component in a weighing system that enables use of Hardy’s core technologies - C2® and INTEGRATED TECHNICIAN® (IT). A summing card with IT allows a weighing instrument operator to switch to the summing card’s internal test circuit and diagnose the entire weighing system from the front panel of the instrument or a remote location over the Internet.

Individual load cells can be isolated from each other for weight and voltage readings, allowing a technician or operator to quickly and safely troubleshoot weighing system faults and anomalies.

Hardy's INTEGRATED TECHNICIAN (IT) core feature helps you troubleshoot your weighing system and diagnose problems from the front of the instrument or via the PLC. Individual load cells can be isolated from each other for weight and voltage readings, allowing a technician or operator to quickly and safely troubleshoot weighing system faults and anomalies

Hardy's WAVERSAVER core technology eliminates the effects that surrounding vibration has on the scale weight signal, providing only true data for fast, accurate weight reading.

Access your instrument from any web browser. Use the incorporated web server to configure parameters from any Ethernet connection. This web server also provides remote access to control instrument and information parameters, further optimizing the production efficiency through real-time data exchange.

7 Tips to improve:

The coordination of your maintenance department

Free DownloadHardy Brand Catalogue

Free DownloadThere are many brands offering industrial weighing solutions on the market. At Risoul, we have over 40 years in the business and we’ve had the opportunity to work with many of these brands. Based on our experience, we have chosen to serve as a Hardy distributor.

In Hardy, we have found a manufacturer with amazing capacity to continuously provide products of superior quality and excellent customer service.

Some of the benefits we value most in Hardy are:

C2 electronic calibration: Provides fast and easy electronic calibration with no need for traditional test weights.

WAVERSAVER vibration eliminator: WAVERSAVER technology eliminates the effects that surrounding vibration have on the scale weight signal, providing only true data for fast, accurate weight readings.

Integrated Technician: This feature helps you troubleshoot your weighing system and diagnose problems from the front of the instrument or via the PLC

Check out our blog where you will find the following articles:

With over 40 years of experience in the field, our philosophy is to offer the best brands and value-added service for our customers. At Risoul, we offer automation, electrical equipment, and industrial network solutions for the following industries:

|

• Automotive • Petroleum |

• Food • Consumer |

• Mining • Manufacturing |

PDI Solutions

Immediately Available Products (PDI) is an innovative concept that enables us to deliver products from 8 of our primary lines within two business days including: panel assembly, automation, variable speed drives, machine safety, measurement, industrial cable, industrial networks, and vision, weighing and visualization.

The best product lines on the market

We represent leading brands in the industry and we work with our commercial partners to offer the best products and latest technology for our customers.

Consulting services for equipment selection and specification

In additional to the sale of electric and automation equipment, we focus on providing our customers with presale technical support, consulting and training.

Support for your project application

We have specialized engineers available to support you in the selection and specification of equipment, standardization, detection of quality improvement opportunities, improvement projects and training seminars.

Large inventory

We have over 18,000 products in stock and 2 distribution centers with the best brands on the market. At Risoul, we are ready to assist you with any project, big or small.

Delivery availability and reliability

We have a logistics staff of over 70 people and more than 40 delivery vehicles that enable us to reliably deliver materials and even make emergency deliveries 24 hours a day, 7 days a week.

DemoBus

This is an innovative mobile demo space equipped with the latest technology that enables you to take the user experience to your workplace and interact with the most up-to-date equipment.

Control and power panel assembly

Comprehensive solutions in control panel cabinets that conform to the UL-508A standard and have been approved by EATON for distribution panel assemblies.

Av. Sendero Divisorio, #400 Residencial Casa Bella, San Nicolas de Los Garza, C.P. 66428